Introducing New Zealand’s newest Biocontainment Laboratory

16 September 2020

The Ministry of Primary Industries’ new National Biocontainment Laboratory is New Zealand’s only approved laboratory for containing and diagnosing serious veterinary diseases.

Not only is its design and construction impressive, but the completion of the project is a major achievement for Master Plumbers member business Hutt Gas and Plumbing.

Project of a lifetime

Scott Adin, one of the directors at Hutt Gas and Plumbing, led the project’s gas, plumbing and drainage team and describes working on the lab as a “once in a lifetime opportunity”.

The firm spent 12-18 months working on the planning phase with the Ministry of Primary Industries and Fletchers Construction, followed by nearly four years of work.

The team had to learn new products and technologies along the way, including electrofusion welding systems, chemical resistant pipework, CPVC industrial pipes and stainless-steel drainage work.

Their outstanding achievement earned them the 2020 NZ Project of the Year at the New Zealand Plumbing Awards.

Plumbing and drainage work

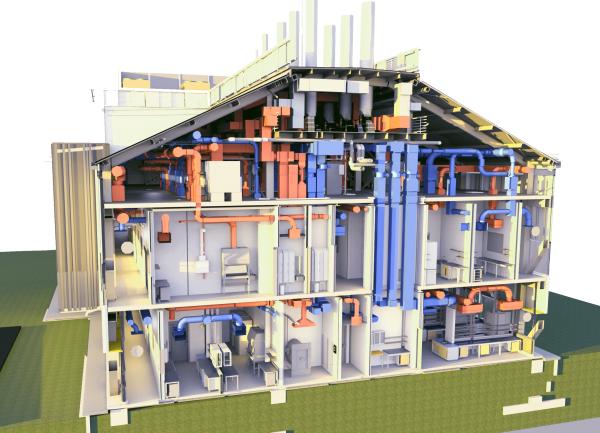

The building is designed with much of the pipework on show. This meant it had to be of a high standard, with a smooth finish for easy cleaning and decontamination.

A complex system of tanks, pumps, and heat treatment systems contains all biomatter. Sensitive air management and fumigation treats all rubbish and wastewater, ensuring any dangerous biomatter isn’t released into the environment.

The lab has three separate drainage systems, so that PC2* and PC3 drainage can remain separated from non-contaminated drainage. There are seven water systems with backflow devices and brake tanks for protection.

In an emergency, individual labs can be closed off for containment and decontamination, whilst the other 16 labs remain functional. There are 50 valves in the drainage systems alone, making the labs safer and more flexible.

A complicated system of flexible hoses will protect biocontainment during an earthquake. They allow all plumbing connections to remain intact with a movement of +/-900 mm.

5 interesting facts about the new facility:

- International design firm Merrick & Company designed the building, with Fletcher construction as the main contractor for the site.

- It's the country’s only PC3 lab with 17 individual lab areas.

- Negative pressure and air filtration systems ensure only clean air leaves the laboratory and advanced safety systems prevent dangerous organisms being released into the environment.

- The building sits on 10 base isolators and 20 slider bearings, designed for the lab to withstand a one-in 2,500-year earthquake.

- In the event of a natural disaster, water, gas, and drainage systems connect to a rooftop 20,000 litre water tank.

*PC – Physical Containment

This blog has been adapted from an article in NZ Plumber magazine, June/July 2020 issue.

You can read the NZ Plumber magazine here